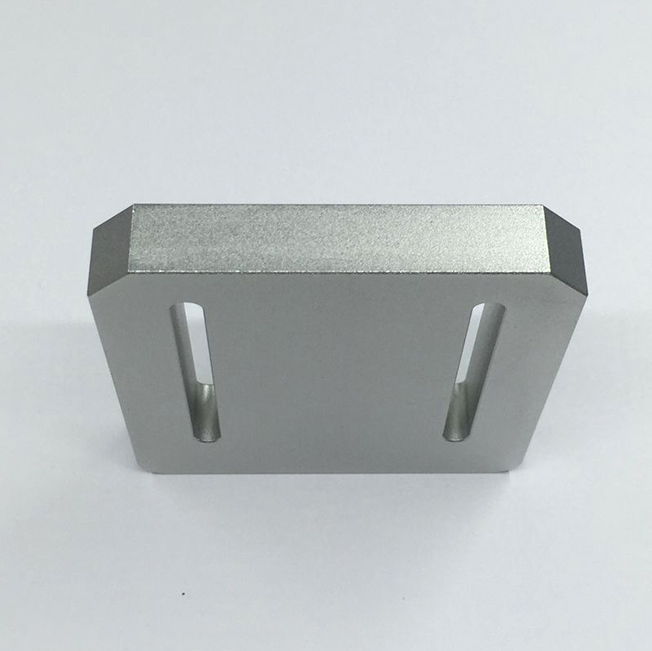

CNC Machining Aluminum Sheet

Get Latest Price| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

Model No.: AL-191

Tolerance: 0.01mm

Sample Lead Time: 3 Days

Material: Aluminum 6061

Machining Processes: CNC Turning

Product Size(mm): 70*55*8

Finish: Clear Anodise

Because the auxiliary time of CNC Machining aluminum sheet parts and accessories has been compressed very short, the loading and unloading of matching fixtures can not take up too much time. In order to simplify positioning and installation, in CNC Machining aluminum sheet parts and accessories, each positioning plane of the fixture should have precise coordinate dimensions relative to the machining origin of the machining center. In CNC machining aluminum sheet parts and accessories, the fixture should have as few components and high stiffness as possible. The fixture should be as open as possible. The lower the space position of the clamping element, the better. The fixture can not interfere with the tool path of the working step, to ensure that the machining contents of the workpiece are fully completed within the stroke area of the spindle. In addition, in CNC machining aluminum sheet parts and accessories, we should try to finish all the machining contents in one clip. When it is necessary to change the clamping point, special attention should be paid to not destroy the positioning accuracy by replacing the clamping point. If necessary, it should be stated in the process document.

| Business content | CNC miliing, CNC Turning |

| Machining Processes | CNC Milling , CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

| Machining Metal | Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

| Parts Size | Milling Parts ( MAX) : Length 1030mm, Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm, Length 750mm. |

| Tolerance | 0.01mm |

| Equipment Capabilities | CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

| Secondary Services of Machining Parts | Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

| Sample | Samples are for free, sample time is 5 days. |

| Delivery | Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

| file format | Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

CNC machining advantages are:

① A large number of tooling can be reduced and the machined parts with complicated shapes do not require complicated tooling. If you want to change the shape and size of parts, only need to modify the parts machining procedures for new product development and modification.

② The machining quality is stable, the machining accuracy is high, the repeatability is high, and it is suitable for the machining requirements of the aircraft.

③ The production efficiency is higher under the condition of multi variety and small batch production, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the optimum cutting amount.

④ Machinable conventional methods are difficult to process complex surfaces, and can even process some unobservable machining parts.

We are looking forward to further contact with you. Have a nice day and thanks for your inquiry!

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.