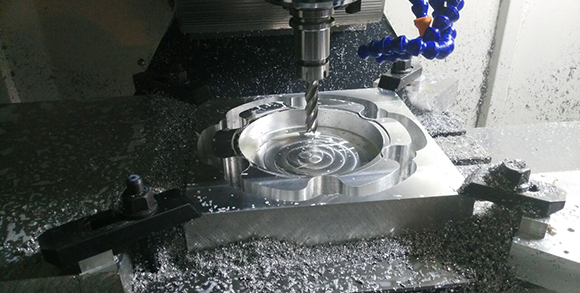

Machining of 7075 Aluminum Parts

Get Latest Price| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

Model No.: AL-045

Tolerance: 0.02mm

Finish: NA

Material: Aluminum 7075

Sample Lead Time: 6 Days

Product Size(mm): ф258*32.6

7075 aluminum alloy has the best strength in the common aluminum alloy, known as extra super duralumin(ESD) .7075 aluminum alloy parts with a good plasticity after solid solution, heat treatment strengthening effect is particularly good, high strength under 150 ℃ , and have a particularly good low temperature strength; poor welding performance; have stress corrosion cracking tendency. 7075 aluminum alloy parts are mainly used for aviation fixtures, trucks, tower buildings, ships, pipelines and other building applications that requiring strength. Such as aircraft components, gears and shafts, fuse parts, instrument shafts and gears, missile parts jumping valve parts, turbines, keys, aircraft, aerospace and defense applications.

Our CNC Milling and turning Machining materials are:

| Plastic | Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

| Copper | Copper, Brass, Bronze |

| Stainless Steel | SUS303, SUS304, (1.4301), SUS316 |

| Steel | Q235, 45 #, A3, 718H, S136, SKD11 |

| Titanium | Titanium alloy |

| Aluminum | 6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

Our CNC Turning Center is equipped with a multi-station turret or power turret. The machine has a wide range of processing performance, Machinable linear cylinder, diagonal cylinder, arc and a variety of thread, groove, worm and other complex parts As well as six lathe. Processing size of the largest diameter can reach ф860mm, a single product the thinnest 0.23mm cnc turnining and CNC Milling Machining materials are: copper / bronze / H62, Titanium / TC4Aluminum 6061, 6063, 6061-T6, 7075, 5052. 2017. 6082. Stainless steel: 1.4305, 1.4301, 316. Steel: Q235,4 5 #, A3, 718H, S136, SKD11... Plastic: POM, Teflon, PA,(PA66) PC, PMMA. Product surface treatment: anode (clear, black, blue, yellow, can also customize a variety of colors). Sandblasting, spraying, Passivation, laser engraving LOGO, silk screen LOGO.

Fast delivery is our advantage, CNC Machining Parts, 3 days to complete the sample, and can be listed according to the work plan to provide emergency expedited service, the fastest sample to complete one day. The factory provides 2 ~ 3 sets of CNC Machining Center for sample production. The workers were divided into two groups to ensure that the machines were produced 24 hours a day.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.