High precision machining brass parts

Get Latest Price| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

| Min. Order: | 1 Bag/Bags |

| Transportation: | Ocean,Land,Air |

Model No.: CU-002

Material: Brass

Finish: NA

Sample Lead Time: 5 Days

Tolerance: 0.05mm

Product Size(mm): ф150*14

Brass has a good CNC Machining performance. Because brass has excellent wear resistance, so tool wear should be considered in the Machining process. High-speed turning and milling Machining Brass can get a good finish. We also provide secondary CNC machining services, the surface finish of CNC brass parts can up to 0.8 after polishing, and polished brass fittings can suitable for use in rotating conductive equipment, such as: motor parts, conductive slip ring.

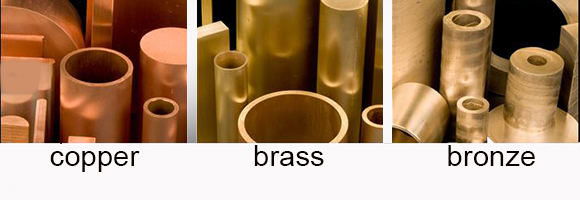

We have three types of Machining Copper:copper, brass, bronze.Copper density of 8.96g / cm3, with excellent electrical conductivity, thermal conductivity, ductility.Using its excellent electrical conductivity and thermal conductivity, machining copper parts are mainly used for generators, wires, switchgear, transformers and other electrical equipment.It is noteworthy that copper will appear sticky knife phenomenon in the machining processing. Brass is added in the copper 25% to 40% Zn and other elements.So the hardness of brass than red copper, but the conductivity is worse than the red copper.Brass high hardness, good wear resistance and corrosion resistance.And has a good mechanical cutting performance.High-speed milling machining of brass can get excellent surface finish,Machining brass pieces are widely used: valves and pipes, radiators, marine parts.Bronze: bronze based on brass joined the Sn, Al, Mn. More abrasion resistance than brass.Bronze in the atmosphere, sea water, fresh water and steam corrosion resistance than brass.Bronze has excellent casting properties, friction reduction performance and mechanical properties.High-speed milling machining of bronze can get excellent surface finish,Machining bronze parts for manufacturing bearings, worm gear, gears.

Buildre Group Co., Ltd is a professional manufacturer of CNC and CNC Machining Services and Molding Services for OEM and ODM parts. And through the ISO 9001: 2008 quality certification system, the production base is located in Shenzhen bright. CNC machining plant covers an area of over 2,600 square meters, the main production of CNC Machining Parts for medical, automotive, communications, electrical, electronics and other industries. Production types include CNC Milling,CNC Turning, grinding, stamping, bending, welding, die casting, drilling, tapping and injection molding. More than 46 CNC machining centers and CNC lathes for your service.

From the procurement of raw materials to CNC Machining Parts shipments, we have established a complete set of quality control system.The whole process of operating workers by SOP operations, IPQC products for each processing steps to detect,Make sure the product meets the requirements before proceeding to the next CNC machining Turning.And 100% full-size inspection of the first machining part. FQC tests the product before shipping and ships the shipping report.

CNC Machining can import your Para-Solid 3D image files, .PDF and IGES,STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.