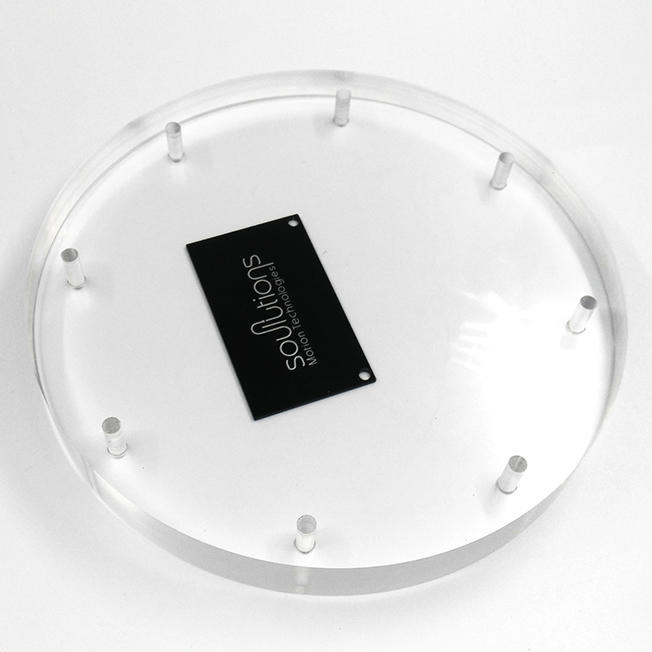

Turning Acrylic CNC Parts

$10≥10Bag/Bags

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 10 Bag/Bags |

| Transportation: | Ocean,Land,Air |

$10≥10Bag/Bags

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 10 Bag/Bags |

| Transportation: | Ocean,Land,Air |

Model No.: PL-022

Material: Acrylic

Tolerance: 0.02mm

Finish: NA

Sample Lead Time: 5 Days

Product Size(mm): ф157.7*8

Machining Processes: CNC Turning And CNC Milling

| Selling Units | : | Bag/Bags |

Acrylic Turning Parts has excellent toughness and light transmittance, high surface gloss, good surface hardness (the same as aluminum), easy Machining , chemical corrosion resistance. Turning Acrylic Parts dimensional stability, not easy deformation.A crylic transmittance of up to 93%.

1 Machining Processes

2 Material ( Machining Metal )

4 Tolerance:0.01mm. Minority size:0.005mm. The measuring instrument can measure the dimension precision:0.001mm.

5 Secondary Services of Machining Parts

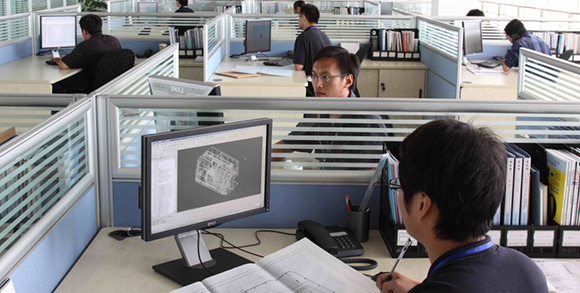

6 Equipment Capabilities

7 File formats

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.