Customized Black Anodizing CNC machining Aluminum Parts

$10≥10Bag/Bags

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 10 Bag/Bags |

| Transportation: | Ocean,Land,Air |

$10≥10Bag/Bags

| Payment Type: | T/T |

| Incoterm: | FOB |

| Min. Order: | 10 Bag/Bags |

| Transportation: | Ocean,Land,Air |

Status: New

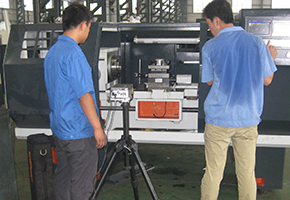

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Motor

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Sustainable

Out-of-warranty Service: Video Technical Support, Online Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Applicable Industry: Other

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Tolerance: 0.01mm

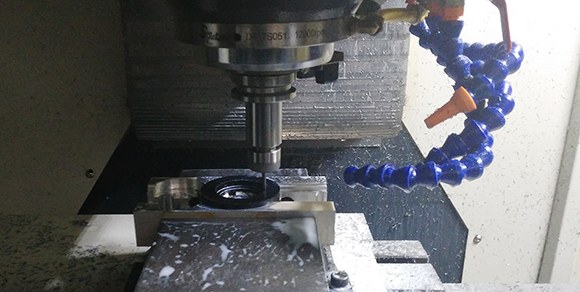

Process: Milling

Lead Time: 3-5 Working Days

Color: Anode Black

| Selling Units | : | Bag/Bags |

Customized Black Anodizing CNC Machining Aluminum Parts

2. Material cooling problem. The workpiece may deform after cooling. This situation is often difficult to avoid. In this case, special attention should be paid to the use of coolant. On-site measurement should also consider the possibility of material deformation.

3. Processing Technology. Unreasonable processing technology can easily cause workpiece size errors. The use of fixtures should be on the basis of ensuring the basic process details of milling CNC Machining (RYH(Hongkong) Aluminum Products, such as "thickness and then fineness, surface and hole, large and then small" or "reduce the number of fixtures, try to use modular fixtures ”) to minimize the Machining errors caused by aluminum chips on aluminum parts.

CNC Machining can import your Para-Solid 3D image files, PDF and IGES, STEP or SOLIDWORKS files. Please send in your 3d work and PDF for a quote.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.